How to Make Liquid Cattle Feed

.jpg)

Solidified in tubs and blocks, liquid feed supplements are suitable for pasture applications to improve animal production over winter or under drought conditions. In liquid form, they can be used to top-dress' a beef or dairy feedlot ration or blend into a total mixed ration' or TMR.

Liquid feed supplements currently are popular among the beef and dairy producers of a few major producing countries. However, there are potential applications in many more countries. Typical LFS macro ingredients: molasses, urea, and saltare widely available worldwide, and basic LFS manufacturing techniques are relatively simple and low-cost compared to dry supplement manufacture of comparable quality.

Moreover, various LFS products are useful in both small-scale and large-scale cattle operations. In order to improve production of grazing animals, LFS products may be solidified in blocks and tubs or presented in liquid form in 'lick tanks'. Also, in liquid form, they may be 'top-dressed' directly on a ration as in a beef or dairy feedlot. In the USA, many dairy farms apply LFS, blended in their total mixed rations (TMRs).

In a typical LFS formula, molasses serves as the carrier for other ingredients, including non-protein nitrogen (NPN) or protein source, and provides dietary energy and enhances palatability. Urea is the typical NPN source, while salt provides mineral nutrients and helps to control intake in order to prevent ammonia toxicity. The current generation of LFS products often includes other ingredients for chemical and physical or mechanical intake control (Davis, 2003). The LFS product also is a good carrier for trace minerals, vitamins, and some medicated additives.

By the late 1970s, there were many LFS feeding systems in American beef feedlots, which prompted development of more sophisticated manufacturing technology. By the early 1980s, LFS products contained all of the macro minerals (with calcium in the form of suspended limestone particles) and micro minerals (zinc, copper, and selenium, for example), plus vitamins, medicated and non-medicated additives, and NPN. In some cases, LFS also contained rumen by-pass protein or fat in a suspension or emulsion system.

In a typical beef feedlot operation, the LFS was pumped from a storage tank at the feedlot, via a liquid flow meter, to a straight truck or trailer mounted mixing wagon'. The mixing wagon mixed LFS in the range of 3-7% by weight with dry feed, then distributed the finished feed along the length of a fence line feed trough. By the mid-1990s, this on-farm LFS application technique had extended into larger dairy farms which increasingly were using TMR rations that incorporated a variety of bulk commodity-type feedstuffs.

Use of LFS offered a number of advantages, including lower farm labour input as well as less feed dustiness, wastage, and overall shrink. Also, with LFS, cattle are less able to sort' feed particles in TMRs. Moreover, any separation of micro ingredients such as vitamins and trace minerals is totally avoided when applied in liquid form. There are reports of improved animal performance in feeding trials showing increased TMR intake with LFS (Shaver 2001, Emanuele 2003); however, more data may be needed to draw a definite conclusion.

In any case, the ruminant liquid feed industry is growing, such that the basic LFS feeding concept has extended into a range of specialised products, including:

'Stress-care' LFS products for newly arrived feedlot steers to overcome shipping stress, often containing extra potassium, yeast culture, and other additives;

Emulsion' LFS products containing 5-8% of a special fat source for texture feeds' for horses, in which the LFS and fat emulsion are blended with whole barley grain, rolled corn, and supplement pellets; and 'Multi-species' LFS products, which include, for example, a product without added trace minerals or vitamins that contains 4% protein and 20% fat for application to dry feeds for dairy cows, beef cattle, swine, and poultry at their respective recommended inclusion levels.

Detailed published technical information on liquid feed manufacturing technology outside North America remains limited. However, the recently published Feed Manufacturing Technology V includes chapters covering an overview of liquid feeds, pressed feed blocks, and poured and low-moisture or cooked' blocks (see http://www.wattnet.com/acb55/stores/1/Feed_and_Farm_C36.cfm).

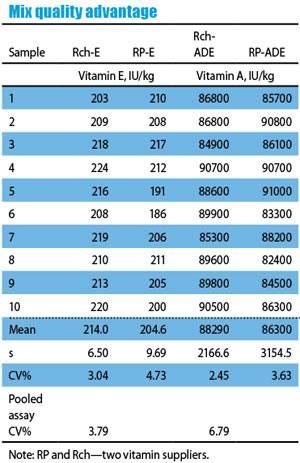

Basic manufacturing processes for LFS offer some significant advantages over dry feed processing. Liquid feed processing can achieve very high mixing homogeneity. For example, mixing homogeneity of vitamins E and A-D-E from two suppliers was tested by direct measuring of the respective compounds. The co-efficient of variation percentage values (CV%) in this mixing study were smaller than the respective pooled lab assay CV% values (see table). These results can be interpreted as 100% homogeneity (Xiong, 1995).

Also, there can be significant energy savings associated with drying liquid co-products used in LFS versus dry feed products. Many wet processing co-productssuch as steep liquor in corn wet milling for starch extraction and production of distiller solubles, as well as other fermentation co-productsmust be dried from their original moisture level (70-95%) to less than 13% in order to be used as dry ingredients. By contrast, only 40% moisture is normally required for liquid feed manufacture. A high moisture level is possible with special treatment proceduresup to 70% in one case (Xiong, 1996). It is important to note that the energy costs to remove water are much less when the product moisture is high (above 40%, for example), than when the product moisture is low (in the range of 13-40%, for example).

Mixing homogeneity of experimental vitamin sources in a non-suspension liquid feed supplement.

Advertisement

Liquid feed is what chemists call a colloidal system', which may be a suspension' system, an emulsion' system or a combination of the two. A suspension system involves solid particles suspended in a liquid phase. An emulsion system is a thoroughly dispersed system of two distinct phases: The hydrophilic phase (having a strong affinity for water) and the hydrophobic phase (lacking affinity for water). Emulsion system LFS consists of oil droplets dispersed in water.

Both suspension and emulsion systems are thermodynamically unstable, such that over time the suspension system's suspended particles eventually settle out from the liquid phase and the emulsion system's oil droplets merge into larger oil drops and separate from the hydrophilic phase. The LFS requires a relatively stable suspension or emulsion system, keeping the product stable for 2 months or longer before the system degrades.

Suspension systems for LFS depend on the viscosity of the main ingredientsvarious types of molasses, whey solubles, brewer and distiller solublescombined with clays and gums to keep particles dispersed throughout the product. Suspension systems demonstrate non-Newtonian or thixotropic properties, whereby the viscosity decreases with agitation, allowing the liquid to be pumped, then increases with stillness, effectively suspending particles.

In LFS emulsion systems, emulsions are thermodynamically unstable and tend to cream' (due to the difference in specific gravity between the two phases), aggregate or flocculate (due to interactions between colliding particles), and coalesce (as a result of free energy gain when larger particles form). Emulsifiers are used extensively to stabilise LFS emulsion systems and the most common emulsifier is lecithin, commercially available as complex mixtures of lipids and phospholipids. Emulsifier molecules adsorbed at the oil-water interface reduce the interfacial tension and reduce the differences in density between the two phases, which increases the emulsion's stability, measured by the change of droplet-size distribution over time.

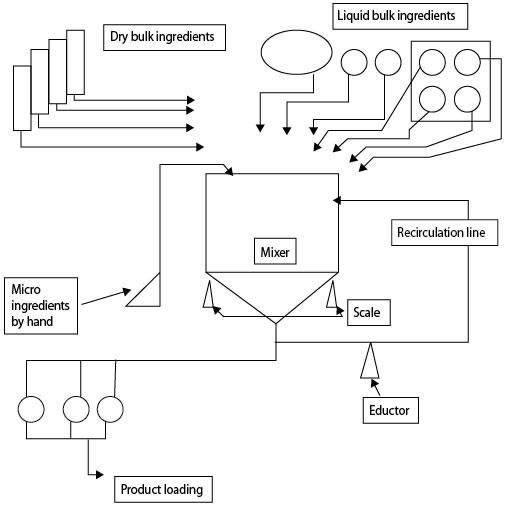

Compared with dry-feed processing, equipment used to manufacture LFS is relatively simple, with relatively low capital investment and labour costs measured on a cost-per-tonne basis (see figure). A critical difference from most dry-feed processing is that in LFS processing all of the processing, handling, and storage facilities for liquid ingredients and finished products must be corrosion resistant. Main LFS equipment includes:

- Storage tanks for liquid ingredients, which may require insulation and heating, with special attention to ingredients that may separate, segregate, or cake surfaces during storage, thus requiring funnel or cone bottom tanks for easier clean-out;

- Bins for bulk dry ingredients and flat storage for bagged ingredients;

- Weigh mixing tank, with capacity which matches largest liquid feed transport vehicle or downstream block forming or tub filling equipment, which includes provision for both dry and liquid ingredient addition;

- Dry ingredient feeder or 'duster' which proportions weighments or volume amounts of ingredients into the liquid vortex in the mixing tank to produce the suspension or emulsion LFS product;

- Liquid ingredient and feed conveyance by pipes and pumps, which may require heat insulation, with eductor pressure differential device in the drain line for recirculation of liquid feed product to the mixing tank.

Basic manufacturing technology for liquid feed supplements (LFS) is relatively simple and low-cost compared to dry supplement manufacture. But LFS initial product quality and subsequent stability depend upon chemical and physical interaction of ingredients in the liquid mixture.

In formulating LFS products, it is necessary to balance both nutrients and to maintain the physical-chemical stability of the finished product, which may depend upon both physical-chemical characteristics and relative proportion of ingredients. In LFS manufacturing processes, proper sequencing of addition of ingredients during mixing can greatly influence the quality of the finished product. Control of unwanted foaming, in which gas bubbles form in the product, illustrates both these points.

Foaming of liquid ingredients and products-in-process can result in serious LFS quality problems. The cause may be biological, such as fermentation of ingredients such as steep liquor, resulting in gas bubbles trapped in the liquid phase. A 5% salt solution or application of a propionate-type mould inhibitor usually inactivates the biological activity and stops foaming (Xiong, 1993c). Foaming also may result from an acid-base reaction forming carbon dioxide (CO2) in calcium suspension products containing steep liquor. Ammoniation of steep liquor is the most effective way to stop this type of foaming. Another advantage of treating steep liquor with 1.5-2.0% ammonia (NH3) is that the viscosity of the steep liquor increases tremendously after ammoniation and thus increases the suspension-emulsion stability of the product.

Foaming also may result from poor quality urea, for example urea with high pH which constantly releases NH3. The ingredient addition sequence may be at fault. For example, foaming may occur if gum is mixed with liquid urea first. One remedy is to mix liquid urea with cane molasses (about pH 5) or steep liquor as a first step. The gaseous NH3 is neutralised by acids in the molasses-steep liquor mixture, converting to ammonium salts. Alternatively, the high pH of the poor quality urea can be adjusted to a pH value close to 7 by adding a strong inorganic acid salt such as hydrochloride.

Both chemical-biological stability and physical or positional' stability are important in LFS products. The product formulation should specify micro ingredients capable of use in LFS products, which may be an issue with medicated products and vitamins because of potential chemical interactions, particularly with minerals. However, research demonstrates a high level of vitamin stability with LFS proper formulation (Xiong, 1995).

Positional stability of a LFS suspension or emulsion product may be measured in a simple way: For suspension products, test the concentration of calcium in the upper and lower portions of a liquid feed column after a certain period of settling (such as 2-3 months); for emulsion products, test the concentration of fat with the same procedure. It is also possible to assay for specific micro ingredients using the same technique to compare upper and lower liquid column concentrations.

Complete references for this article are available from Dr Xiong, who plans to report on LFS ingredients in greater detail in a future article.

Source: https://www.wattagnet.com/articles/162-basic-technology-making-liquid-feeds-for-ruminants

0 Response to "How to Make Liquid Cattle Feed"

Post a Comment